Water Insulation

Human beings always want protection from atmospheric conditions as part of their nature. It is obvious that the caves provided protection from cold and windy conditions even before the historical age. In order to prevent the adverse effects of rain and storms, the rain water has become something to be avoided in the caves and later in tents. The first water insulation efforts were necessitated for getting protection against rain water. This need caused the solution of hiding underneath the rocks and subsequent usage of tents as a form of roof. The thing to watch out is the water coming above. However, with the technological changes that have taken place in the structures, the direction of water to be prevented and the conditions of it have changed as well. Not only the water coming down from the clouds, but also the underground water has to be taken into consideration.

The contribution of settling down in certain places rather than nomadic way of life contributed to this process immensely. As the nomads started to feel the necessity of settling in a single place and let their roots grasp the soil, the buildings likewise set their foundations deep into the ground. Now it is necessary to deal with water that comes from under the ground.

In order to have structures with long operational life with comfort and health, they have to be designed in the right manner and they shall be protected against the external forces. One of the most effective elements for the structure is the water.

The structures are subject to water through;

- Precipitation like rain and snow,

- The humidity of the soil and the rain absorbed by the rain and utility waters,

- Water usage in wet areas such as bathrooms, toilets and such other places,

- The pressured and non-pressured underground waters on which the building has been place on top of it

- and accumulation of evaporated steam originating from inside on the roof, facade and other exteriors.

It is not possible to eliminate the threat of water as explained herein above; however it is possible to stop water entering into the building. Any kind of work carried out on the outer shelf of a building for the purpose of protecting the building against water and humidity is called "water insulation".

The biggest thread to a building in terms of its operational life is "water". The water that leaks into a structure has a corrosive effect on the fittings and reduces their sections and therefore reduces the carrying capacity of them in a considerable amount. Furthermore, the water within the structural elements freezes in cold seasons and evaporates in the hot seasons and hence disturbs the concrete's integrity and results in development of cracks in the concrete. Apart from this, the ground humidity or the sulphates that are in the ground water enter into chemical reaction with the concrete and deteriorate the composition of the concrete. This will affect the operational life of the structure and endurance of it in an adverse manner. Furthermore, water causes the development of harmful molds and fungus and other organic substances.

The water insulation is carried out in order to protect the structural elements that over the ground from rain water, and harmful acidic atmospheric gaseous as well as protecting the structural elements that are below the ground level from underground waters and adverse effects of the humidity. In order to have effective water insulation in place, the insulation work must cover all structural elements from the bottom of the structure to all the way up. The floors that are sitting right on the ground, the balconies and exterior walls, the roofs and foundation walls are all subject to insulation work.

A new terminology such as Richter scale, tsunami and ground survey has entered into our lives after two powerful earthquakes experienced in 1999. The corrosion was also a new concept. The reason for destruction of so many structures was the corrosion. And the reason for corrosion is not having proper water insulation. After having such a bitter experience the water insulation of the structures still not being totally comprehended.

The biggest effect of water on the structures is about the operational life of the building and safety. This events shows that water insulation has a vital importance.

PVC Membrane Applications

WHAT IS A PVC MEMBRANE?

AN IDEAL MATERIAL FOR ADVANCE TECHNOLOGY STRUCTURES

PVC is an abbreviation of "Poly Vinyl Chloride" and consisted of the first letters of the compound.

PVC is a plastic compound developed by suitable and necessary additives and has a long operational life span and has endurance against atmospheric conditions.

Approximately 23 Million ton/ year and 5.5 million ton/year of the product consumed per in Europe and rest of the world respectively.

PVC is especially used in the industries where long operational life span (20 - 50 years) is required. With this propriety, the product is used in the pipes, window frames, cable insulation and insulation membranes, in floor covering materials for many years. With the insulation membranes that are used in tunnel constructions an operational life span of 100 years is expected

When compared with the other plastic compounds, PVC is produced with nominal petroleum refraction. With the electrolysis of rock salt, the chlorine appears as "waste product" and bonds with ethylene and utilized it a useful manner and it is not released to the atmosphere. It emerges as Vinyl chloride PVC when petroleum and chlorine electrolyzed with crack-gas (disintegration gas) from ethylene Along with many vinyl chloride molecules, polyvinyl chloride (PVC as short) may evolve as a polymer; in another words, a polymer may be bonded together with its chains that are in the same shape. A powder form is obtained from the end result of the vinyl chloride that is in gas state. It is solid and rough and it is not possible to work on it before processing it. Additives are needed in order to process it.

PVC is a formless (shapeless) plastic compound. In another words there is no crystallization data and therefore it is completely transparent (clear). Due to its composition, it allows integration of plastic additives into its structure. In this manner, the properties of PVC can be combined in an extraordinary manner and at a result PVC can be used in many areas. There is no any other plastic compound like PVC that can be used for multiple purposes. By adding suitable additives, PVC can be processed at around 180-200°C without segregation. The forming of this plastic compound is possible at lower temperature ranges. In such type of processes, the raw materials can be joined together, pipes, hoses, profiles, folios and plates may be extruded (divided in the form of a net), the wires are covered, insulated guide rails are shaped in cylindrical form, ready to use parts are formed by means of repelling and parts with empty bodies are produced by blowing.

The PVC has been kept in the agenda by the political groups; we would like to make some explanations relating to PVC within the framework of this text.

1st Argument: "PVC production from Vinyl Chloride"

It is suggested that vinyl chloride induce cancer and therefore people who are working with PVC or the producer of it or the people who process PVC materials are threatened with cancer.

However, the reality is that, all the dangers that may be caused due to working with PVC are known today. Today, the PVC production is carried out only in closed reactors. The monomer ratio remaining in the monitors can be checked during the polymerization process and when the remainder ratio shows 1 ppm value, the reaction process will be halted. The meaning of 1 ppm is as follows: It means 1 particle in 1 million particles and in another word (to make it simple by means of visualization): 1 person with a red hat in a crowd of 1 million people with blue hats.

No problem has ever been encountered during the process of PVC. Prognose AG company has conducted a research on the request of "Greenpeace" and it has been determined that if any other substance is used instead of PVC, an additional cost of 3 billion Euro must be spared. The German Federal Ministry for Construction, Housing and Urban Planning stated in its report of "Using PVC products in the Construction Industry" that there is no finding to point out that utilization of PVC products causes any health concerns.

2nd Argument: "Stabilizers with heavy metal contents (firmer)"

In this context, there are thermal stabilizers containing Cadmium (Cd) and Lead (Pb). This application can be carried out with stabilizers containing Barium (Ba) and Zinc (Zn) or Calcium (Ca) and Tin (Sn) under prevailing conditions. Cadmium is prohibited in EC region as well as in Switzerland. Many of the water insulation membrane producers have ceased making stabilizers with Lead and Cadmium components for many years now.

3rd Argument: "Softeners"

Generally speaking, in order to call a substance as poisonous, a small amount of it must cause a harmful effect. In this context the softeners are not poisonous. The softeners are in none of the poison classification according to any law or regulation. The toxicity level of the softeners is much lower than those substances that we use in our daily lives; for instance Sodium chloride (table salt). The softeners and especially DOP and DINP are researched the most and according to the researches carried on rodents (mice and rats) it is determined that no carcinogen effect has been found even such animals when they were subject to these substances with doses corresponding to environmental quantities during lifelong application period. Despite this fact, the softeners are consumed by the microorganisms easily. According to the result of the researches conducted, the softeners do not accumulate in water, soil or in the air.

4th Argument: "PVC during fire"

It was suggested that hydrochloric acid and dioxin develop when PVC is burnt. However, the reality is as follows: The gaseous matter that develops with the fire contains toxins all the time regardless of the material that is burning. The danger poisoning caused by primarily from carbon monoxide (CO); that is released from not completely burnt material and generally is the reason for the death. The PVC that melts, burns or extinguishes by itself releases many other separable products beside hydrochloric acid and dioxin and according to the level of scientific information we have today , these elements do not add toxin additives to the burning gaseous. That means the poisoning is caused primarily due to CO. It is odorless, causes fainting and is a deadly poison. With the creation of hydrochloric acid, a 5 ppm density can be detected by the human senses. It activates the human glands and in this manner it provides a warning. Under such conditions, there is ample time for getting out to a safer environment.

Especially in the case of bitumen insulation membrane materials used in the roofs, the product has a high burning property and therefore causes a fast advancement of the roof fires with high temperatures and possible burning liquid flow downwards from the deck sheet. In this respect, the PVC based water insulation membranes provide much better specifications when compared to bituminous membranes.

5. PVC Recycling

An important advantage of PVC is that it can be recycled. The PVC is used widely in our buildings today and they can be processed with an addition of various softeners as per the requirement. These materials van even be recycled after 25 or 30 years without encountering any problems, in other words, they can be included in the cycle. Therefore, the scrap PVC should not need to be burned or stored as a waste. That means, it will neither pollute the water nor the soil. The insulation membrane materials made out of bitumen, there is an end point in its life cycle and they can only be destroyed by burning.

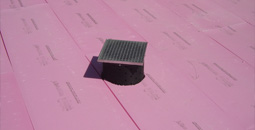

Application of Bituminous Membrane

The bituminous membrane may be used in the foundation, curtain, basement, garden, terrace and roofs of the structures and as well as on the bridges, viaducts and other constructions that are subject to different level of loads for the purpose of water insulation and preventing the adverse effects of water in order to provide comfortable living sections.

The bituminous membrane may be used in the foundation, curtain, basement, garden, terrace and roofs of the structures and as well as on the bridges, viaducts and other constructions that are subject to different level of loads for the purpose of water insulation and preventing the adverse effects of water in order to provide comfortable living sections.

As it can be understood from its name, it is a bitumen based insulation material and it can have many different polymers that strengthening its structure. These polymers may add many diverse strength factors to the material and they also provide easy application and an excellent insulation.

Bitumen reinforced with polymers, may be used with polyesters or glass wool with different tensile, brake tear and endurance points. The bituminous membrane is suitable for diverse climate conditions and suitable with the carrying structure's various details and these properties put the bituminous membrane apart from other insulation materials.

The application of bituminous membrane is carried out with torch flame. It is an easy application and provides long terms protection. It prevents water and humidity to get into concrete structures hence protects the fittings from corrosion. It is mandatory to protect the fittings of the structures and not to overload the structures considering the location of our country in respect to earthquake zones. In this respect, the products that are covered with slates in different colors are ideal with its light weight and visuals so that the structure is not overloaded and pleasant view is obtained.

The application of bituminous membrane is carried out with torch flame. It is an easy application and provides long terms protection. It prevents water and humidity to get into concrete structures hence protects the fittings from corrosion. It is mandatory to protect the fittings of the structures and not to overload the structures considering the location of our country in respect to earthquake zones. In this respect, the products that are covered with slates in different colors are ideal with its light weight and visuals so that the structure is not overloaded and pleasant view is obtained.

Conipur Applications

CONIPUR, is an unique BASF miracle that has two components with seamless one piece product that has 400% stretching ability , protecting its performance between -40 and + 120 degrees, with endurance to shock temperatures of 250 degree, resistant to chemicals and fire (DIN 4102). It does not allow condensation at the roof. It has extraordinary strength against tearing, breaking and ware. It does not contain solvents and has no weak points. Can be placed at a high rate of 1000 m2 per day and it gets hardened within 15 seconds after application. It is possible to walk over it in five minutes. There is no risk of fire during implementation due to cold application process. With its property of covering over the cracks, it provides definite solution to all risky insulation problems. It has exceptional long operation life

Application of Materials by means of Coating

Concrete Injection Applications

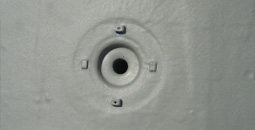

It is a water insulation system in which the polyurethane material with single or double component not containing a solvent is injected into the gaps in the concrete and to the hair cracks from negative side (from the opposite side of the leak ).

HOW DOES IT WORK?

The material that has a similar viscosity with water is injected into the concrete with pressure. The material penetrates the concrete just as water would penetrate by going through the cracks and spaces and gets stuck under pressure and freezes within seconds. After completion of curing process, the material will not be subject to any interference from outside or will not be dissolved and penetration of water will be ceased. It will protect the concrete and reinforcement from the adverse effects of the water.

USAGE AREAS:

- Preventing water entry into the ground concrete in the structures.

- Insulation of the foundation curtain concrete which cannot be interfered from outside.

- Preventing leakage from outside into the water tanks.

- Inside application of buildings where it is not possible to apply from exterior due to the height of the building.

- On stone walls and floors where classical method of application is not possible.

- In all concrete structure where intervention from the source of water is not possible in vertical or horizontal plane.

Thermal Insulation (Exterior Wall Coating)

Sound Insulation

Fire Insulation

The developing technology and industrialization and increase of population causing spread of urban areas. This is resulting in increase of fire risk and consequently increased in financial and personal losses. Fire is uncontrolled burning. In order to have a fire, tree components that make the fire triangle is needed; burnable material, oxygen and source of heat.

All types of furniture, curtains, wall papers and similar objects are all flammable. The needed oxygen can be found in the air. The heat sources such as a burning cigarette, electrical short circuit, sun rays, heating stove and stove as well as some chemical reactions and heat originating from friction can bring the flammable materials to ignition temperature and consequently a fire starts. Considering that flammable objects and oxygen are part of our lives and furthermore, the energy needed to start an ignition are all around us since we are surrounded by technological devices, the probability to having a fire is not as low as we think.

When we talk about protection from fire, we all thing about fire extinguishing systems, smoke detectors and other warning systems. As they are called active protection systems, play an important role in the fire safety but they only activate after a fire actually starts and they may not fully function due to a mechanical failure. For this reason, besides the active preventions, structural preventions must be in place for stopping the fire spread within the structure or to the neighboring structures and decreasing the adverse effects as well as evacuating the people safely out of the structure. In this manner, before the fire enlarges, the possibility of intervention to fire by the fire brigades would be made possible. Limiting the damaging effects of fire and ensuring the safety of occupants and the property is called "fire insulation".